Challenges

Cook & Associates

Management Consultants

Cook & Associates

Management Consultants

Challenges

As with any new initiative, there will be some challenges that have to be met before you begin seeing a payback. If you start by building a sense of pride, it will increase the chance of success. In other words, create an environment where people know they have to be good to work in the organization.

The cultural challenges will vary based on current conditions and the overall labor environment. The situation can be improved by being totally transparent with all involved parties and letting everyone understand what they will get out of the Program:

However, no matter what the challenge, management must always reserve the right to manage.

Acceptance and morale can actually go up with the proper implementation of a Labor Management Program.

Labor Management Pay-Back

Companies sometimes think that stories of productivity gains are overrated, but there are a lot of what appear to be documented stories that show productivity gains in the 20% to 30% range.

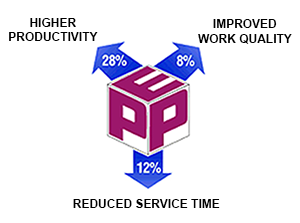

Our proven, practical, human-oriented Labor Management Program empowers staff and enables managers to make the right choices — yielding impressive results:

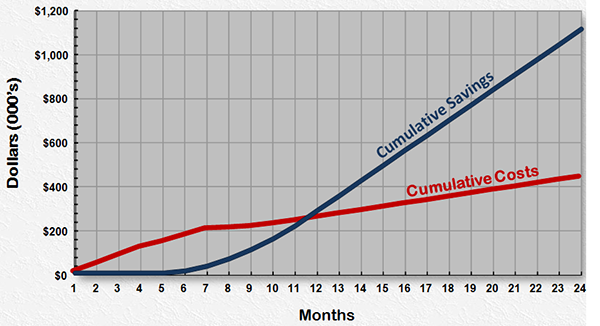

Break-Even

Our experience shows that project break-even, based on cash flow analysis, is between 10 and 14 months.

Case Studies

Remember, most productivity gains are achieved by using efficient methods and reducing idle time — not by putting employees on a treadmill! Here are some of the ways that our clients have realized significant savings:

Third Party Processor: Did not know where temps were and what they were doing. Installed centralized temp assignment and used PEP to monitor performance. Temps reduced from 120 to 40.

Annual savings $1,000,000.

Multiple Fashion D.C.'s: Implemented the PEP Performance Review module to identify employees with a 100 hour Productivity Index less than 70%. Retrained, or if unsuccessful, dismissed employees.

Annual savings $900,000.

Specialty Retail D.C.: After being on the program for four years, and achieving initial productivity gains, implemented the PEP Pay for Performance Incentive module. Overtime virtually eliminated.

Annual savings $500,000.

Bottom line: There are significant gains that can be achieved by implementing an effective Labor Management Program.